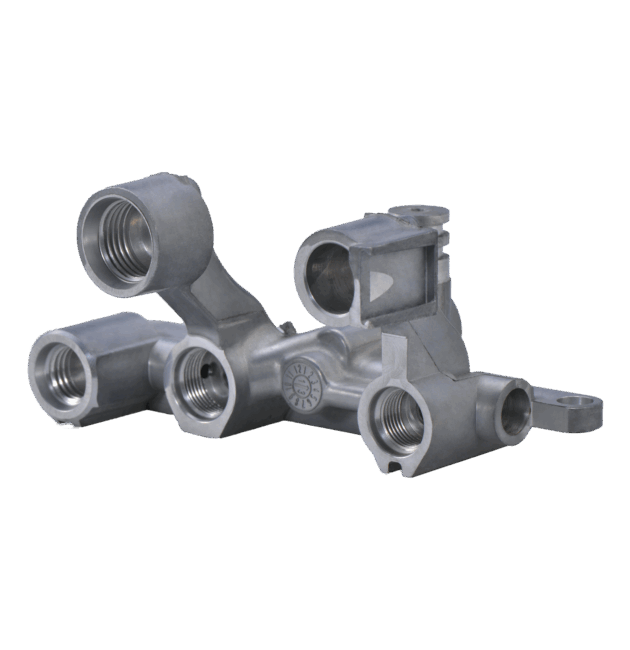

As your experienced manufacturing partner for die-casting, we provide a comprehensive service, including tool manufacturing. With a diverse selection of metals, nearly limitless possibilities unfold. In addition to aluminum, magnesium and zinc alloys, we also manufacture your parts from materials such as stainless steel and many others. To ensure that your components precisely meet your requirements, we offer comprehensive post-processing and finishing.

Our ordering process is straightforward. Simply upload your drawings or send them by e-mail. Typically, you'll receive your personalized quote as soon as the next day.

1

Submit product data

Request your quote online or via email. We will review the drawings and technical details of your inquiry.

2

DFM-Feedback

If desired, we will get back to you with tips on die-cast-compatible design. In collaboration with you, we assist in achieving the best manufacturable solution.

3

Get your Quote

As soon as the final design has been determined, we will send you a final quote for your order.

4

Manufacturing, Quality control & Delivery

assemblean takes care of the entire manufacturing process, conducts quality control, and delivers the parts to the desired destination.

Custom-made parts from your preferred material - We source all the metals and alloys you need.

We offer a wide range of surface treatments tailored to your design and functional requirements.

As your reliable partner, we handle the entire order process: from procurement and production to the timely delivery of your finished die-cast parts.

We already verify the dimensional accuracy of the components during the manufacturing process. Our on-site experts ensure the highest quality standards through a thorough final inspection of all parts.

The most commonly used die-casting alloys are based on aluminum, magnesium, or zinc. However, among the materials available to us are also stainless steel, brass and silicon tombak. Do you need a specific alloy not listed here? No problem! We manufacture your parts with your preferred material.

Aluminum offers very high thermal conductivity, high process stability and high resistance to corrosion and weathering. Aluminum die casting also enables the production of parts with high complexity and low wall thicknesses. Frequently used alloys are:

Magnesium alloys have a lower hardness and strength than comparable AI alloys, with high elongation at break and good castability. Due to their heat resistance, they are used in the automotive sector, for example in the engine compartment. Frequently used alloys are:

Zinc alloys are preferred for high-quality, dimensionally stable and precise castings with tight tolerance requirements. The high melting point of zinc makes it perfect for high-temperature applications. In addition, these alloys are good conductors of electricity and heat. Often used are:

We also offer the following surface treatments for finishing and wear and corrosion protection:

Die-casting is a widely used manufacturing process for producing complex metal parts in large quantities. In this process, molten metal is injected into a mold to take the desired shape as it cools and solidifies. This casting mold, also known as a die, consists of two halves that separate from each other after the casting process.

Key considerations in die-casting production include material selection, precise temperature control and casting pressure. After solidification, the finished part is removed from the mold. Die-casting enables the production of highly precise and durable metal parts with tight tolerances. It is an extremely efficient process widely used in various industries with specific demands such as the demanding automotive industry.

* By submitting the form, you agree to the assemblean privacy policy.