assemblean realizes your production project.

From prototype to series production.

>35

manufacturing

services

500+

verified

production partners

3

own

production sites

>100.000

produced

products

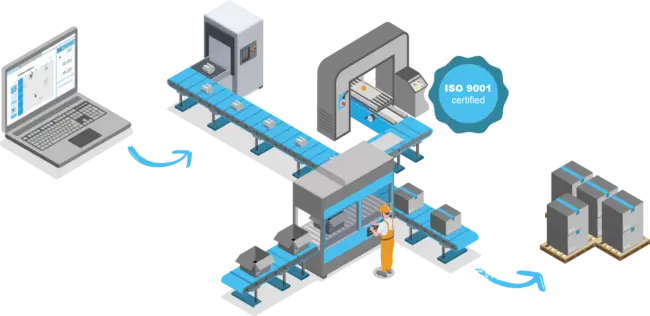

A partner for your production parts, assemblies or products - procurement, production and assembly

We produce your product exactly according to your requirements, no matter how complex your components are. Thanks to our own production facilities and our global network, we create the most favorable offer with the best possible implementation for you.At assemblean, you receive production, surface treatment, component assembly and logistics from a single source so that you can focus on your core business.

We provide support early on during product development and optimize the development, especially with regard to manufacturability and cost-effectiveness.

We provide support early on during product development and optimize the development, especially with regard to manufacturability and cost-effectiveness.

We also procure the necessary purchased parts without additional costs for the assembly / product. For more complex purchased parts, we are happy to take over the sourcing and thereby additionally optimize the economic efficiency.

We also procure the necessary purchased parts without additional costs for the assembly / product. For more complex purchased parts, we are happy to take over the sourcing and thereby additionally optimize the economic efficiency.

Including mechanical manufacturing processes, such as turning, milling, injection molding, die casting & post-processing, such as painting, coating, polishing & electronics manufacturing, such as circuit board fabrication, wiring.

Including mechanical manufacturing processes, such as turning, milling, injection molding, die casting & post-processing, such as painting, coating, polishing & electronics manufacturing, such as circuit board fabrication, wiring.

From manual to semi-automated to fully automated assembly, including joining techniques such as welding, gluing, riveting, etc., we handle the assembly process and optimize it on an ongoing basis.

From manual to semi-automated to fully automated assembly, including joining techniques such as welding, gluing, riveting, etc., we handle the assembly process and optimize it on an ongoing basis.

Automated quality control directly in the production process and continuous quality and functionality checks by our experts on site.

Automated quality control directly in the production process and continuous quality and functionality checks by our experts on site.

We are also happy to take care of all components of logistics, including supply chain coordination, so that everything is delivered to its destination at the desired time.

We are also happy to take care of all components of logistics, including supply chain coordination, so that everything is delivered to its destination at the desired time.

"With assemblean's support, we can better manage the high complexity of our manufacturing process and relieve internal capacities. They manufacture and assemble various subassemblies for us flexibly as required."

Katharina von Jan

"assemblean supplies us with mutliple modules and helps us sourcing multiple components. We were able to significanlty lower our costs with the help of assemblean and speed up our processes."

Philipp Herrmann

"Xiaojun and her team accompanied us from development to production and managed to complete all steps from sourcing to assembly in three months. Through her help, we were able to signifificantly shorten our time-to-market."

Alisa Möhrke

"assemblean has been supporting us in development for a long time, giving us feedback on producibility and tips to produce our Twike more economically. They help us directly in sourcing and producing different modules."

Martin Moescheid

"We had an idea for which we could not find a supplier despite a long search. assemblean took over everything for us from product development to the finished product. Thank you for the good and uncomplicated cooperation!"

Manfred Berens

Thanks to the combination of our own production facilities and large network, we always find the best solution to manufacture your parts at a very competitive price.

You send us your requirements and we take care of the rest.

You get access to our huge network of production partners. Your data is of course protected by strict agreements with our network.

We are ISO 9001 certified. Our in-house quality assurance enables us to test every part we deliver as required.

* By submitting the form, you agree to the assemblean privacy policy.