Assembly Manufacturing

- Mechanical and mechatronic assemblies

- All technologies available: welding, bonding, soldering, screwing, riveting, and many other connections

- Customized assembly services: Depending on quantity and requirements, we carry out manual, semi-automatic, or fully automated assembly operations

- One-stop solution: Procurement of purchased parts, manufacturing of production components, joining processes & assembly, quality inspection & functional tests

Assembly Service by assemblean

As your expert in assembly manufacturing, we bring together comprehensive knowledge in mechanics and electronics. Our expertise extends to the production of both mechanical and mechatronic assemblies. As your sole point of contact, we assume overall responsibility with in-house manufacturing and assembly, coordinating all interfaces with our partners.

We manage the entire process, from planning to functional testing. This includes procurement of purchased parts, manufacturing, assembly, and, if needed, support in development, design, and optimization. Our integrated approach not only increases efficiency but also ensures higher level of quality assurance.

Our straightforward and efficient inquiry and ordering process enables you to implement your projects quickly and effortlessly. Simply upload your CAD data, drawings, and/or bills of materials (bom) or send them via email. We will respond promptly, discuss your project and provide you with a customized quote in the shortest possible time.

In 4 simple steps to your finished assembly

1

Submit Product Data

Request your quotation online or by e-mail. Send us your CAD data, drawings and/or bill of materials. We will get back to you as soon as possible.

2

Project Coordination / DFM Feedback

We collaborate with you to coordinate your project, optionally including design-for-assembly tips. Subsequently, we commence with the detailed planning.

3

Get your quote

As soon as the final design has been determined, we will send you a final quote for your order.

4

Manufacturing, Quality Control & Delivery

assemblean takes care of the entire manufacturing process, conducts quality control, and delivers the parts to the desired destination.

Our Processes

Thanks to our own production facilities and collaboration with trusted manufacturing and assembly partners, we are capable of producing your modules using a variety of manufacturing technologies and joining techniques.

Manufacturing Technologies (mechanical)

- CNC Machining

- Injection molding, die casting, vacuum casting

- Sheet metal processing

- 3D-Printing

Manufacturing Technologies (electrical)

- Cable packaging

- Printed circuit board production (PCB production)

- Wiring

Assembly and Joining Technologies

- Welding

- Gluing

- Screwing

- Soldering

- Plug connections

- Clamp connections

- Threaded connections

- Rivet connections

- Bolt connections

- Form-Fit connections

Why order assemblies from assemblean?

Benefit from these advantages

Lower Costs

You have to deal with significantly fewer parts. Many individual orders become one consolidated order. No more coordination of the corresponding supply chain and scheduling. All of this reduces the overall costs.

Reduced Complexity in Final Assembly

No more complex goods receipt and picking processes You receive fully functional assemblies that can be seamlessly integrated into the final assembly. This results in shortened assembly and lead times for your end product.

Easily Scalable

With us, you can scale from initial prototypes to large volumes in no time. Simply produce as needed to respond quickly to changes in demand or customer orders.

Automated quality control

We already verify the dimensional accuracy of the components during the manufacturing process. Our on-site experts ensure the highest quality standards through a thorough final inspection of all parts.

You Stay Flexible

We take care of immediate rescheduling in case problems arise, if a planned supplier is unavailable at short notice or quick reordering is necessary. This reduces your dependency on individual suppliers!

IP/Know-How Protection

Your data is secure with us! We only share the data in anonymized form with our partners. Additional protection is ensured by manufacturing critical components in our three proprietary production facilities.

Become a satisfied Customer of assemblean today

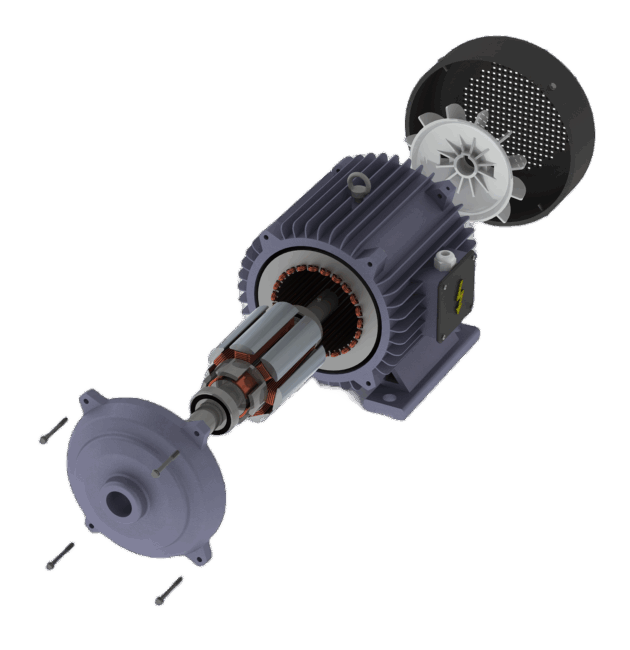

What is Assembly Manufacturing?

In assembly manufacturing, multiple individual components are assembled to create a larger, functional unit or product. These assemblies can be made from various materials and parts produced through different manufacturing processes.

The assembly follows a clearly defined sequence, where individual components are connected, assembled, and, if necessary, post processed to create the final product. This process can involve various steps such as welding, screwing, gluing, or other joining techniques, depending on the requirements of the assembly.

Assembly manufacturing is widely used in various industries such as the automotive industry, electronics production, mechanical engineering and others where complex products need to be assembled from multiple parts. The focus is on efficiency, precision, and quality to ensure that the manufactured assemblies meet specific requirements and standards.

Additional Resources

Book personal meeting

Contact Us

* By submitting the form, you agree to the assemblean privacy policy.