As an experienced partner in sheet metal processing, we offer a versatile range of possibilities. Thanks to our own manufacturing facilities and an extensive network of partners, we can produce a wide variety of sheet metal parts through bending and cutting processes. Whether it's small series or large orders, we manufacture sheet metal parts of any complexity and dimensions according to your specifications. Additionally, we provide comprehensive post-processing to ensure that your components precisely meet your requirements.

Our ordering process is straightforward. Simply upload your drawings or send them by e-mail. Typically, you'll receive your personalized quote as soon as the next day. The delivery time for the manufactured parts is only 14 days, depending on the quantity and complexity.

1

Submit product data

Request your quote online or via email. We will review the drawings and technical details of your inquiry.

2

DFM-Feedback

If desired, we will get back to you with design-for-manuacturing tips. In collaboration with you, we assist in achieving the best manufacturable solution.

3

Get your Quote

As soon as the final design has been determined, we will send you a final quote for your order.

4

Manufacturing, Quality Control & Delivery

assemblean takes care of the entire manufacturing process, conducts quality control, and delivers the parts to the desired destination.

Custom-made parts from your preferred material - We source every metal you need.

We offer a wide range of surface treatments tailored to your design and functional requirements.

As your reliable partner, we handle the entire order process: from procurement and production to the timely delivery of your finished sheet metal parts and assemblies.

We already verify the dimensional accuracy of the components during the manufacturing process. Our on-site experts ensure the highest quality standards through a thorough final inspection of all parts.

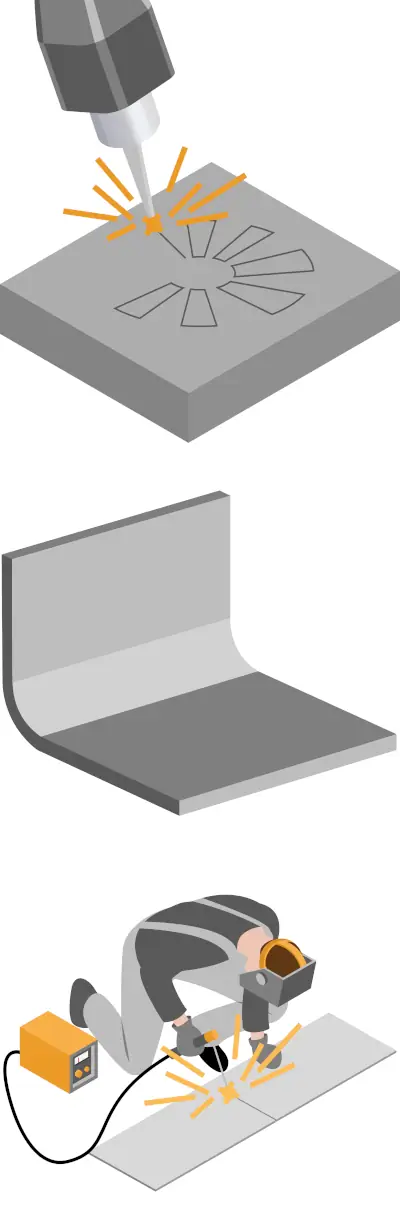

Processing into (Welded) Assemblies using various joining technologies.

Do you need a specific alloy that is not listed here? No problem! We manufacture your parts with your preferred material.

Aluminum alloys are characterized by their excellent corrosion resistance and high strength. Due to their excellent weldability and machinability, they find versatile applications in the automotive industry and mechanical engineering. Some commonly used alloys include:

Steel alloys are characterized by their good machinability, weldability, and high strength. Steel alloys have broad applications in mechanical engineering. Some commonly used alloys include:

Stainless steel alloys exhibit good temperature and corrosion resistance as well as high elongation and tensile strength. Additionally, they are characterized by good weldability and formability. Some commonly used alloys include:

We offer the following post-processing methods for refinement, strengthening, and protection against corrosion:

Sheet metal processing is a significant manufacturing technology for transforming flat sheets into diverse forms. Various processes such as cutting, bending, punching and welding are employed. The choice of the appropriate process depends on factors such as sheet metal type, thickness, and specific requirements.

Sheet metal processing is used to create complex components and assemblies such as housings, frames, body parts, electronic components and more. The technology finds widespread application in various industries, from automotive to electronics.

* By submitting the form, you agree to the assemblean privacy policy.