Assembly process planning can make a big difference in making production more efficient. Assembly process planning means that a simplified assembly process is considered in product design. As a result, assembly can improve production and reduce costs!

Basics

During assembly, the product goes through a large part of the value creation process.

During product design, not only the functionality of the product is influenced, but also the assembly sequence and the individual processes required.

In addition, a number of technical and organizational errors and difficulties can occur during the assembly process, which can complicate the production process. Therefore, the effort required in assembly is determined early in the product development process.

Finally, the required effort and the successful control of the assembly process are decisive for the profitability of the entire production.

Construction suitable for assembly

The most important principle is to prevent unnecessary assembly operations and enable cost-effective processes. The aim is to design the subsequent assembly operations in such a way that the product can be assembled with simple procedures and little equipment.

It is always a matter of finding a compromise between technical and economic aspects. What equipment do I already have? Existing equipment can justify a technically non-optimal solution for a process from an economic point of view.

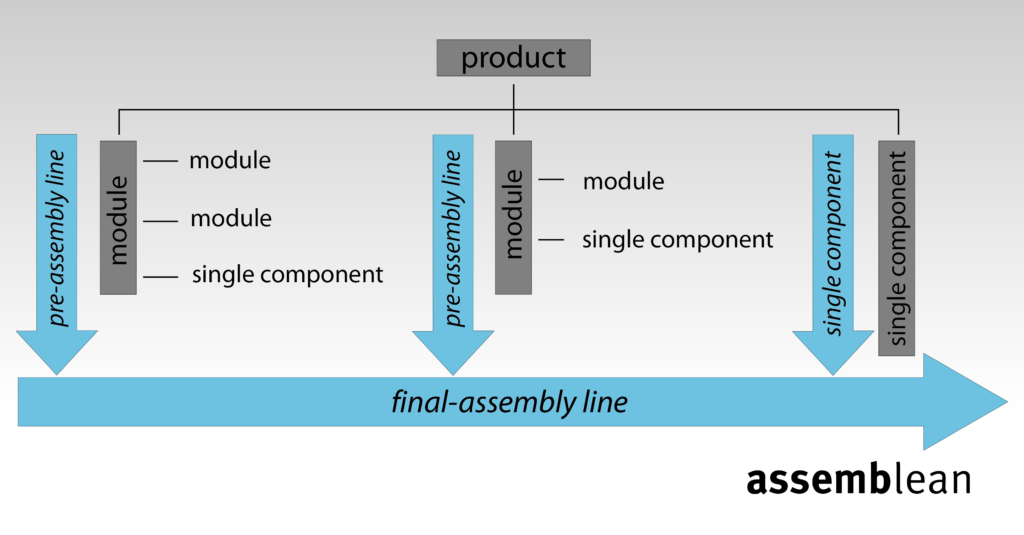

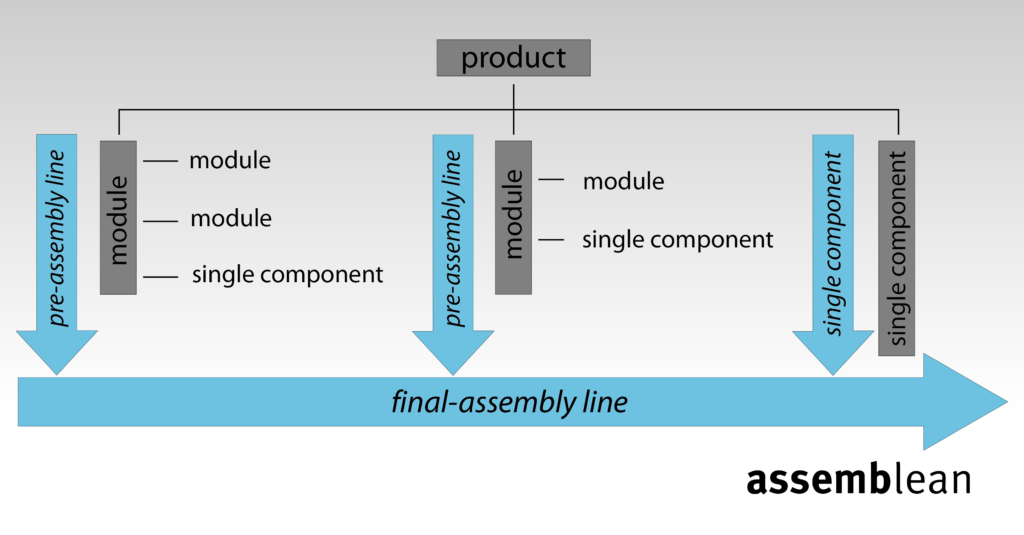

In addition, complex products should be modular. For example, assembly can be divided into pre-assembly and final assembly. This way, individual complex assembly tasks can be grouped and divided into individual pre-assembly lines. With a modular product structure and the shifting of assembly tasks to pre-assembly,...

- can the lead time be reduced.

- can improve accessibility and automation around pre-assembly.

- there is a possibility to outsource assembly tasks to subcontractors

Summary

So how can assembly process planning improve production? In summary, assembly process planning helps:

- reduce production costs - even if they are difficult to predict in the early stages of the design process. You'll see the financial impact when assembly begins.

- identify and reduce cost drivers at an early stage.

- to make the production process as a whole more efficient.