The injection molding process is one of the most commonly used methods for manufacturing plastic parts. A crucial component of this process is the gating system, which controls the material flow and significantly influences the quality of the final product. Among the various types of gates, the film gate holds a special position. This article provides a detailed insight into the functionality of the film gate, its advantages, applications, design considerations, and future trends.

Importance of the Gate in Injection Molding

Role of the Gate

The gate is the part of the injection molding machine that directs the molten plastic from the machine nozzle into the mold. A well-designed gate ensures an even material flow and minimizes defects such as air inclusions or uneven filling, which significantly improves the quality of the final product.

Types of Gates

There are several types of gates, including the edge gate, pin gate, and film gate. Each of these gating methods has specific characteristics and applications tailored to the requirements of the respective workpiece.

The Film Gate

Definition and Description

The film gate is a specialized type of gate in injection molding, characterized by its broad, film-like shape. Unlike pinpoint gates, the film gate distributes the material evenly over a larger surface area, leading to improved and more uniform mold filling.

Construction and Design

A film gate typically consists of multiple thin, parallel channels that guide the material across the mold. This design allows for even plastic distribution and reduces internal stresses in the workpiece, enhancing the stability and quality of the final product.

Functionality of the Film Gate

Material Flow

In a film gate, the plastic moves in the form of a thin film through the channels. This distribution ensures that the pressure is evenly spread across the entire mold surface, enabling complete and consistent mold filling. The broad material flow minimizes the risk of air entrapment and ensures uniform wall thickness in the final product.

Cooling Properties and Workpiece Filling

The larger surface area of the film gate improves heat dissipation during the cooling process. Efficient cooling is crucial to shorten cycle times and enhance the quality of the plastic part. Additionally, the even distribution of material helps to minimize stress and warpage in the workpiece, improving product durability and precision.

Advantages of the Film Gate

Reduced Gate Marks

Due to the broad connection between the film gate and the workpiece, the visible gate mark is minimized. This is particularly beneficial for aesthetically demanding parts, as the marking is less noticeable and easier to remove or conceal.

Improved Surface Quality

The even distribution of plastic results in a more consistent surface finish of the final product. This reduces the need for post-processing and improves overall production yield in injection molding.

Consistent Material Flow

The film gate ensures a continuous and even material flow, reducing the likelihood of defects or incomplete mold filling. This enhances the repeatability and consistency of production, which is particularly advantageous for mass manufacturing.

Minimization of Defects

By ensuring uniform pressure distribution and better mold filling, common injection molding defects such as air inclusions, brittleness, or uneven wall thicknesses are minimized. This leads to higher quality and reliability of the manufactured parts.

Comparison of the Film Gate with Other Gate Types

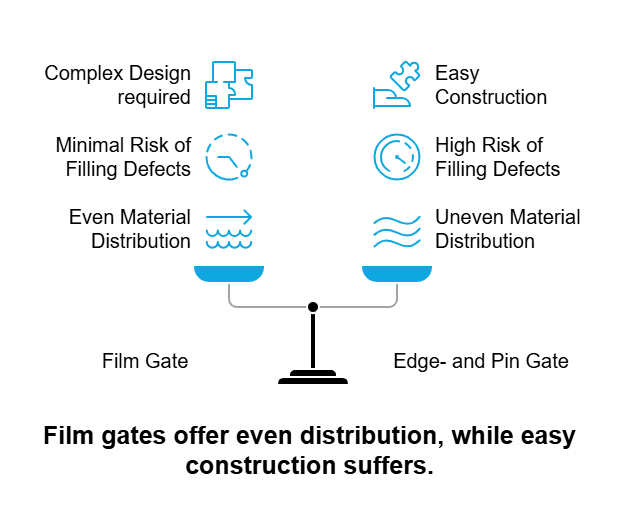

Edge Gate

The edge gate consists of a single channel running along the sides of the mold. Compared to the film gate, the edge gate offers less uniform material distribution, increasing the risk of filling defects. The film gate, in contrast, ensures more consistent filling due to its wide distribution.

Pin Gate

The pin gate is a pinpoint gate that directs material into the mold from a specific point. While it is easy to construct, it can lead to uneven material flow in complex geometries. The film gate provides the advantage of a more uniform distribution over a larger area.

Strengths and Weaknesses of the Film Gate

The film gate combines the advantages of several gate types by ensuring even distribution like an edge gate while minimizing visibility like a drop gate. However, its construction can be more complex and requires precise design considerations to achieve optimal results.

Practical Applications of the Film Gate

Industries and Components

The film gate is widely used in industries that demand high surface quality and dimensional accuracy in their plastic parts. Typical application areas include the automotive industry, medical technology, electronics, and consumer goods manufacturing.

Example Components

- Automotive interior panels

- Housings for electronic devices

- Precision components for medical technology

- Toys and household products

Film Gate Design Guidelines and Best Practices

Designing a Film Gate

Several factors must be considered when designing a film gate:

Conclusion

The film gate is an advanced gating method in injection molding that enables more uniform and high-quality production through its broad material distribution. Its benefits, such as reduced gate marks, improved surface quality, and minimized defects, make it a preferred choice in many demanding applications. With ongoing technological advancements and increasing requirements for precision and efficiency, the film gate will continue to play a key role in the injection molding process.

👉 If you have any questions or an idea for production, feel free to send us a request!