In mechanical engineering, assemblies are far more than just loosely screwed-together parts. They form complex, functional units that serve as the foundation for efficient and flexible machine development. Below, we present typical assemblies, explore the interface between mechanics and electronics, and explain key design and standardization principles.

What Are Typical Assemblies in Mechanical Engineering?

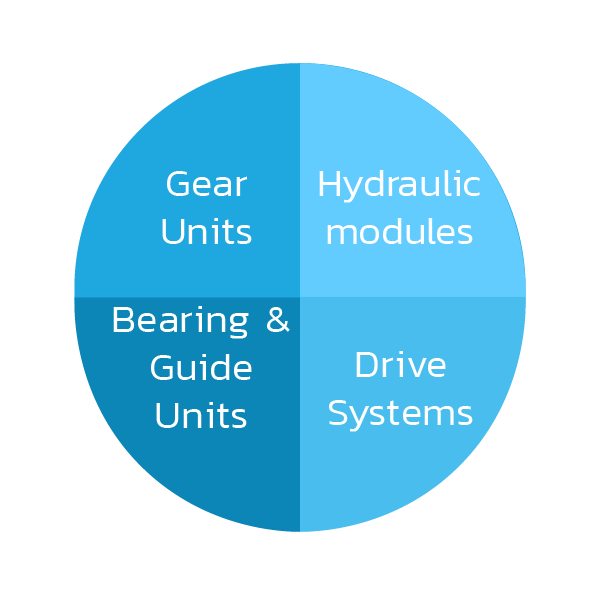

Assemblies in mechanical engineering are specifically designed to meet the high demands of industrial applications. Common examples include:- Gear Units These mechanical assemblies convert torque and speeds and are essential for power transmission in machines. They consist of gears, shafts, bearings, and housings, and must be precisely manufactured and assembled.

- Hydraulic Modules Hydraulic assemblies control force and motion using fluids. They contain pumps, valves, accumulators, and piping, and are used in heavy machinery and systems, such as in construction or vehicle engineering.

- Drive Systems Mechanical components combined with electric motors and sensors form mechatronic assemblies that offer high flexibility and controllability – for example, in automated production lines.

- Bearing and Guide Units These ensure low-friction movement and precise positioning of machine parts.

Mechanical vs. Mechatronic Assemblies

While mechanical assemblies consist solely of fixed components (e.g., gears, bearings, housings), mechatronic assemblies incorporate additional electrical and electronic elements such as sensors, controllers, and actuators. This results in intelligent assemblies that not only perform mechanical functions but also monitor, control, and adapt processes.This integration requires a tightly coordinated development process in which mechanics, electronics, and software work seamlessly together based on established principles and standards.

Design-to-Assembly Principles – Efficiency from the Start

To enable efficient production and assembly of assemblies, companies in mechanical engineering rely on the Design-to-Assembly (DTA) principle. The product is specifically designed so that assembly:- is as simple and fast as possible,

- minimizes potential errors,

- uses few and standardized fastening elements,

- features modular and easily accessible components.

This saves time and costs and sustainably improves the quality of assemblies.

Examples of Design-to-Assembly Principles

In line with Design-to-Assembly, the number of parts is reduced by using integral components to eliminate additional operations.Another goal is to reduce steps and standardize individual components. This can be achieved through uniform interfaces or reduced assembly directions. Positioning and alignment aids may also be added.

In terms of assembly, pre-assembled modules can be formed. Additionally, especially in automated assembly, flexible components such as cables or hoses should be avoided.

Requirements and Standards in Mechanical Engineering

Assemblies must meet numerous technical and regulatory requirements:- DIN standards (e.g., DIN ISO 2768 for dimensions and tolerances) ensure dimensional accuracy and interchangeability.

- CAD data form the digital foundation for development, production, and quality assurance. Modern CAD systems enable virtual testing, optimization, and seamless integration into manufacturing processes.

- Safety and quality standards, such as machinery directives or EMC standards, are particularly relevant for mechatronic assemblies.

Among other things, EMC (Electromagnetic Compatibility) standards regulate the placement and commissioning of devices that may emit electromagnetic interference. They are also relevant for CE certification, a key product marking.

By complying with these standards, functionality, safety, and long service life are ensured.

Assemblies in mechanical engineering are highly complex systems that combine mechanical precision with modern electronics. Their design and manufacturing follow proven principles that ensure assembly-friendliness and standard compliance. This makes assemblies the foundation of powerful, reliable, and maintainable machines – from gear units to hydraulic modules and intelligent mechatronic systems.

assemblean – Your Partner for Mechanical Engineering Assemblies

The development and manufacturing of complex assemblies in mechanical engineering require not only technical know-how but also experience in holistic process design – from construction to production, assembly, and quality control.We support you in implementing your assemblies efficiently, in compliance with standards, and with perfect fit. Our services include:

- Consulting on optimizing assemblies for easy assembly and modular structure

- Production and pre-assembly of both mechanical and mechatronic assemblies

- Precise implementation of CAD data to ensure manufacturing and compliance with all relevant standards

- Structured quality testing including full traceability

- Flexible manufacturing from prototypes and small batches to large-scale series

Thanks to our extensive expertise and modern production capacities, we can tailor solutions to your specific needs and take pressure off your team with customized support.

Contact us to successfully realize your mechanical engineering assembly projects together.